Product Description:

The silo wall vibrator is used to prevent and eliminate the "blocking" and "tower arch" phenomenon caused by internal friction, deliquescence, electrification, composition segregation and the like of various silos; it can also be used to remove various silo walls and pipelines. The material can also be used as a vibrating feeder, a vibrating conveyor, a vibrating funnel, a vibration source of a vibrating chute, and the like. Widely used in mining, metallurgy, chemical, building materials, machinery and other industries.

The silo wall vibrator is used to prevent and eliminate the "blocking" and "tower arch" phenomenon caused by internal friction, deliquescence, electrification, composition segregation and the like of various silos; it can also be used to remove various silo walls and pipelines. The material can also be used as a vibrating feeder, a vibrating conveyor, a vibrating funnel, a vibration source of a vibrating chute, and the like. Widely used in mining, metallurgy, chemical, building materials, machinery and other industries.

Working Principle:

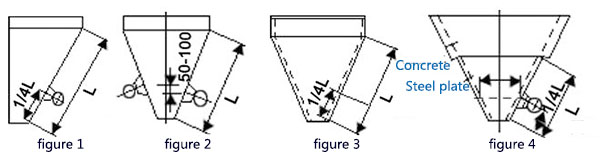

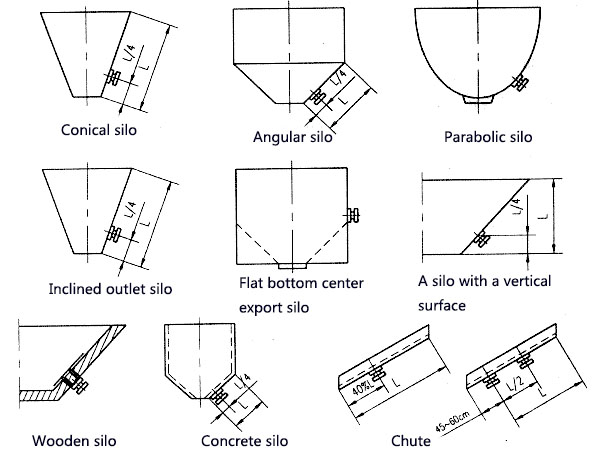

Installation position of the wall vibrator

The silo for storing pure coarse materials, regardless of the form, should be equipped with vibrating plates in the silo for this kind of material. The silo wall vibrator/anti-blocking device should be welded to the vibrating plate.

Chute: The silo wall vibrator/anti-blocking device should be welded to the part of the chute that is easy to stick and block materials.

All-steel silo: the silo wall vibrator/anti-blocking device should be welded to the silo wall.

For all concrete silos and silos with reinforced steel bars, a vibrating plate should be laid in the silo, and the wall vibrator/anti-blocking device should be welded to the vibrating plate.

The upper part is a concrete silo, and the lower part is a steel hopper. The wall vibrator should be welded to the wall of the dry hopper.

Example (inclined outlet silo): installation steps of the silo wall vibrator

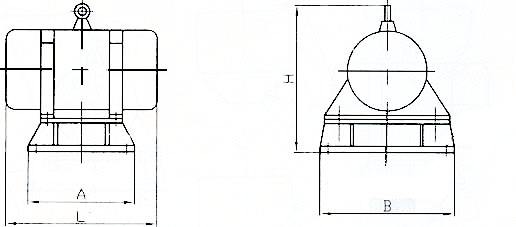

| LZF series Horizontal vibration motor |

LZF series Horizontal vibration motor

|

LZF series Horizontal vibration motor

|

LZF series Horizontal vibration motor

|

| Model | power(KW) | series | Exciting force(KN) |

| LZF-3 | 0.09 | 2 | 1 |

| LZF-4 | 0.15 | 2 | 1.5 |

| LZF-6 | 0.22 | 2 | 2.5 |

| LZF-8 | 0.37 | 2 | 5 |

| LZF-10 | 1.10 | 2 | 10 |

| LZF-12 | 1.50 | 2 | 20 |

| LZF-15 | 2.20 | 2 | 30 |

Package:

If you have any needs or requirements,pls contact me without hesitate!!!

Tel:0086-373-5433765

Whatsapp/wechat:86-15836009878

Email:cndahan@dahanmachine.com