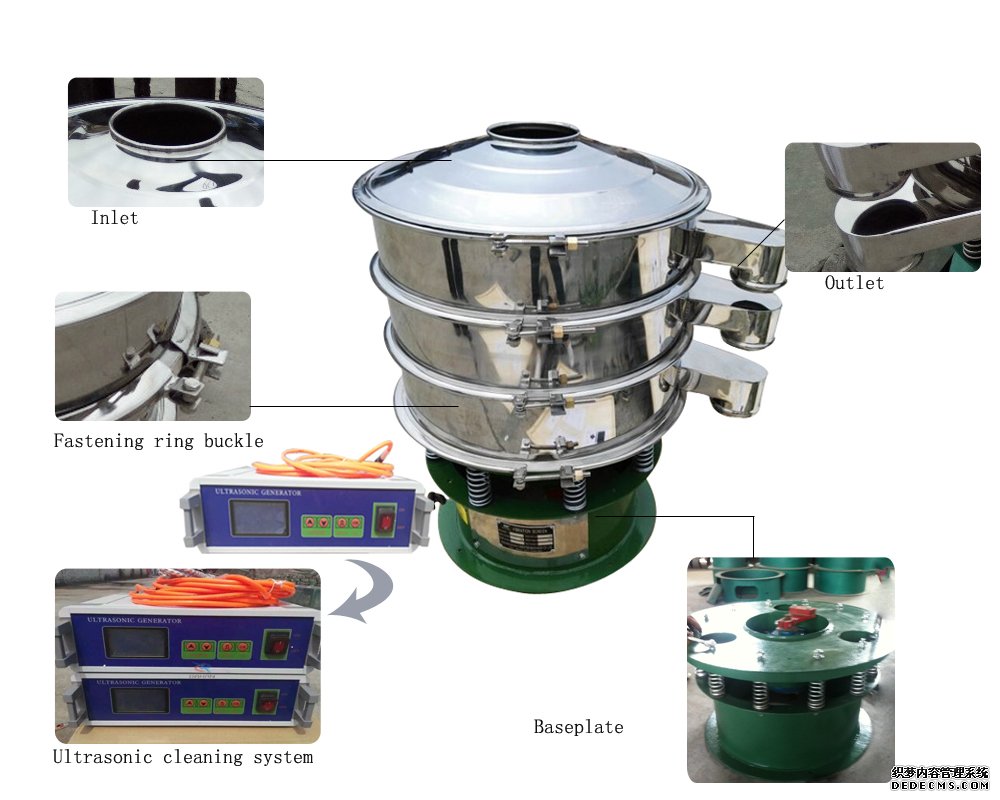

Function of Ultrasonic Vibrating Screen

1. Ultrafine powder screening: Really solve the screening problems of the characteristics material of strong adsorption, adhesion, sticky, high static, high density, ultrafine powder, etc.

2. Solve the network blockage: convert 220V, 50Hz electric energy into 38KHz high frequency electric energy, input the ultrasonic transducer, and turn it into 38KHz mechanical vibration, so as to achieve the purpose of screening and cleaning the network, making it easy to screen fine powder Increasing the penetration rate and reducing the clogging of the screen.

3. Reduced costs: eliminates mesh damage normally associated with mechanical cleaning devices, increasing mesh life

Q:How to choose the suitable machine?

A:The proper selection of the vibrating screen depends on the material, number of layers, every mesh size, capacity, material moisture, viscous and corrosive etc:

Name and feature of the raw material?

Aim of using: get rid of impurity, filtration, grading

Handling capacity: kg /h, L/h

The raw material size: (mesh or mm)

How many final materials you want, or how many layer you need?

Local power supply (voltage and frequency)

Note: You had better send us the relevant pictures about the details.